Allseeds is one of the largest oilseed processors in Ukraine and owns a state-of-the-art, multifunctional oil extraction plant located in the deepest port in Ukraine, Port Pivdennyi. The plant is a strategic asset of the company, ensuring a high level of efficiency in oilseed processing and stable production of goods that meet international quality standards.

The capacity of the oil extraction plant is 2,200 tons per day for sunflower seeds, 1,500 tons per day for rapeseed, and 1,200 tons per day for soybeans. This enables the company to meet not only domestic market needs but also effectively export products to international markets.

During the construction of the plant, Allseeds actively utilized advanced technologies that optimize the yield of finished products, reduce energy consumption, ensure a high level of automation, and comply with environmental standards. By implementing these technologies, the company has significantly increased the plant's efficiency and minimized its environmental impact.

The selection of suppliers and contractors for the plant’s construction was conducted through a tender process, ensuring maximum transparency in cooperation and the selection of the best solutions for project implementation.

The suppliers of technologies and equipment for the plant include Andreotti Impianti (Italy), BUHLER (Switzerland), Westfalia (Germany), Bosch (Germany), and Harburg Freudenberger (Germany). For energy-saving solutions, the plant was equipped with boiler equipment operating on sunflower husk, supplied by the Belgian company Vyncke. This solution significantly reduced energy consumption and improved the energy efficiency of production.

The technical audit and quality control of equipment and technological processes were carried out by the company Tebodin (Netherlands), ensuring high technical execution standards and compliance with international requirements.

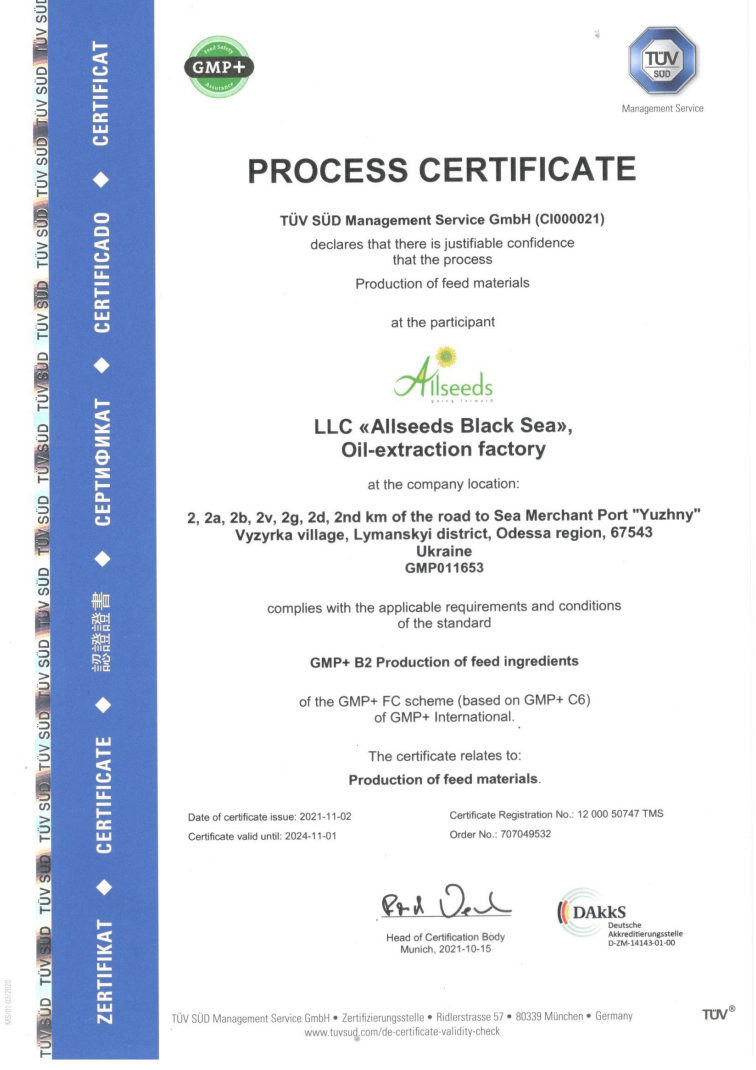

International Quality Standard: Our Plant Has Received TÜV SÜD Certification

Our production facility has successfully passed certification and received TÜV SÜD Management Service GmbH 30696—one of the most prestigious international certifications, confirming compliance with the highest standards of safety and quality.

The certification covers the production of sunflower, rapeseed, and soybean oil for food purposes, as well as meal for animal feed and feed ingredients. This ensures strict adherence to technological requirements, raw material quality, and control processes at every stage of production.

Receiving the TÜV SÜD certificate strengthens trust among our partners, opens new opportunities for international cooperation, and reaffirms our commitment to high standards in production.

Cerfiticates